Our product List are as follows :

- Microwave Plasma Chemical Vapor Deposition (MPCVD) Reactor

- Plasma Enhanced Chemical Vapor Deposition (PECVD) Reactor

- Engineering Plasma-Favorable Materials

- Produce Fusion Graded Plasma Resilient Materials

- Super-hard-Thermally conductive-wide bandgap materials

Microwave Plasma Chemical Vapor Deposition (MPCVD) Reactor:

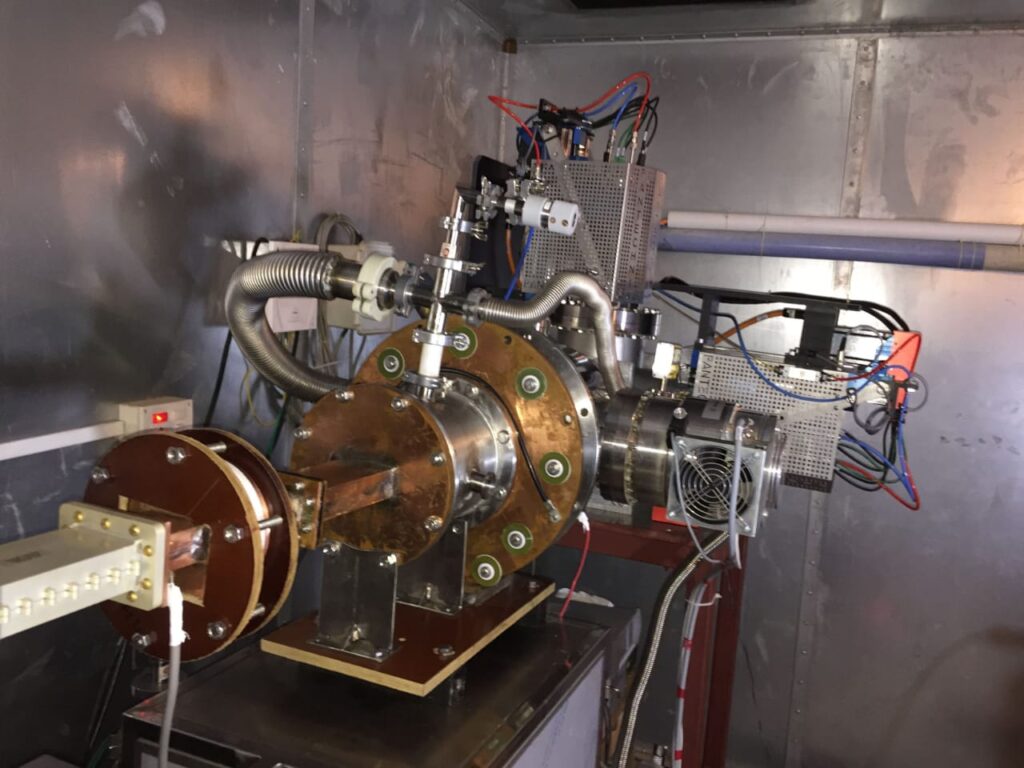

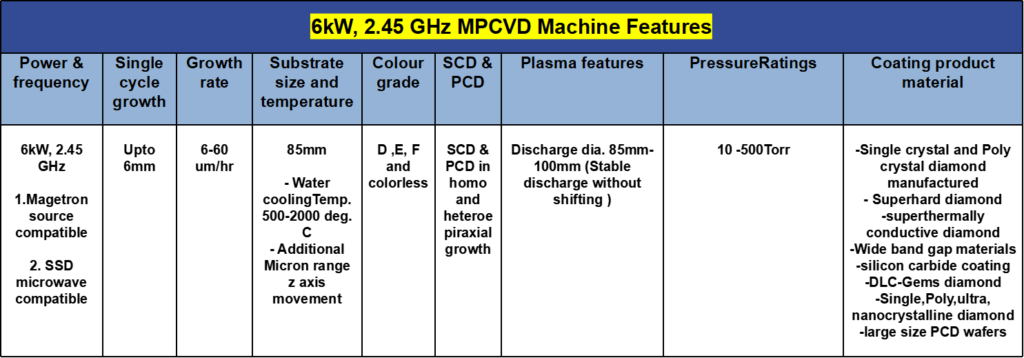

(a) 6kW, 2.45 GHz Microwave plasma chemical vapour deposition system for diamond growth applications.

The MPCVD reactor system offers interesting features in the competitive market worldwide at reduced cost, better production yield, energy-efficiency and large area deposition.

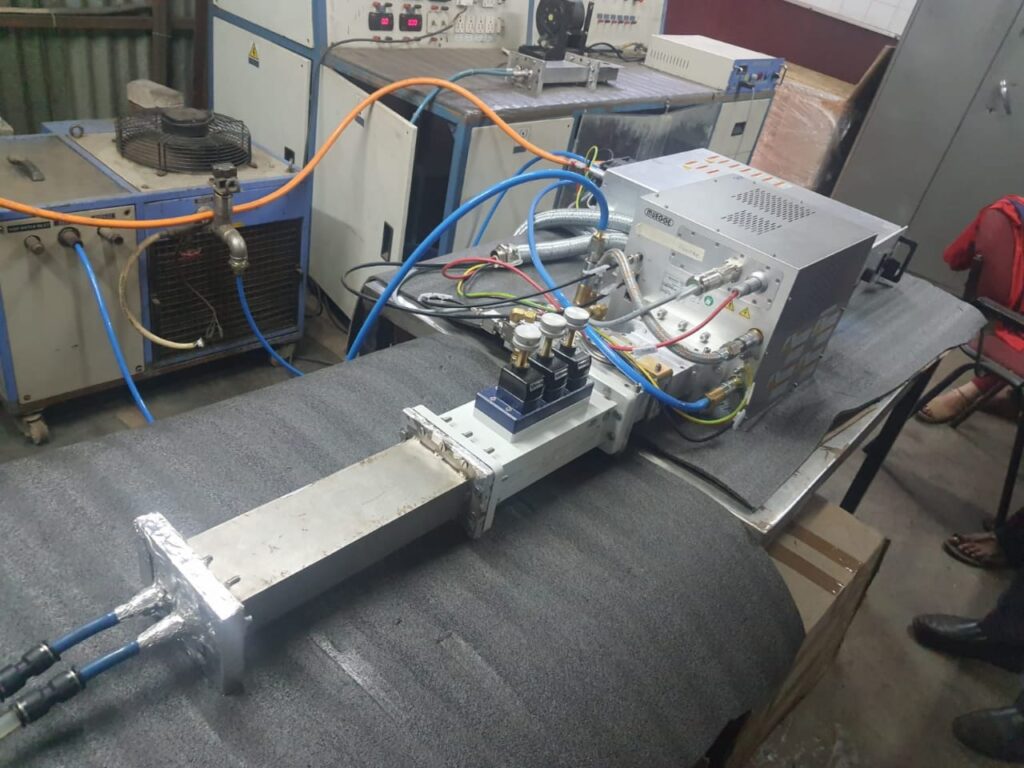

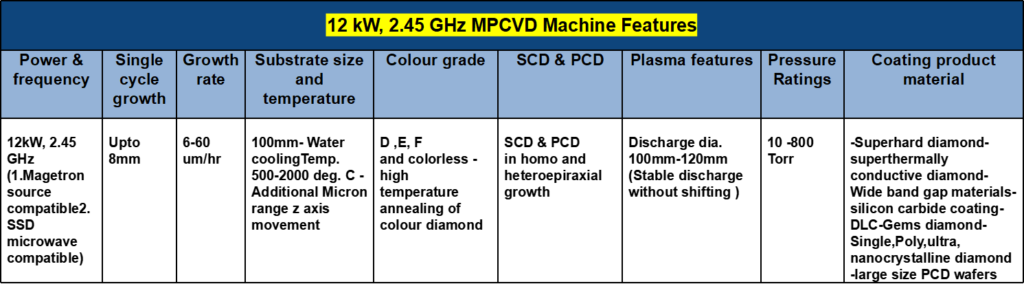

(b) 12kW, 2.45 GHz MPCVD reactor systems for diamond coating applications.

The indigenously developed plasma reactor with substrate movement mechanism facility offers cost-effective design, productive and commercial ready reactor. Some of the features are in the following

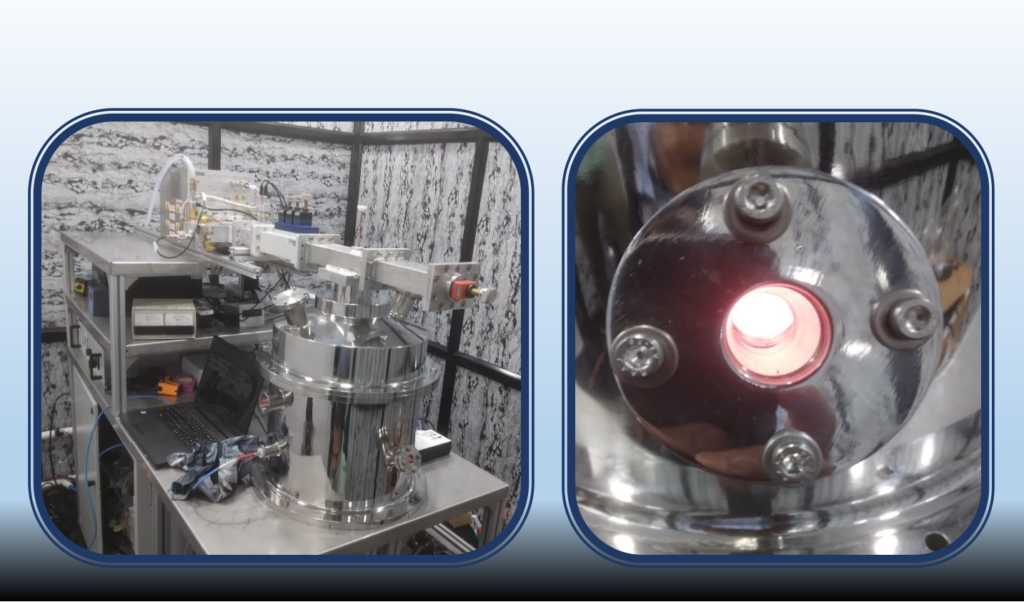

(c) 75-100 kW, 915 MHz MPCVD machine to grow diamond with a large area deposition (300mm substrate size) and high growth even up to atmospheric pressure.

The machine is capable to operate with solid state microwave generator for better plasma control, stability, single time growth to make running cost-effective final market ready coated product.

| SSD GaN based Microwave generator | Cavity magnetron based Microwave source |

| Microwave output excitation spectrum is stable and broad around the frequency of operation | Very unstable and non-monochromatic output excitation spectrum |

| Broad spectrum with stable bandwidth can be utilized in coating machines during the growth processes | Growth pattern over course of time is not predictable due to shift/ variation of output frequency spectrum from magnetron |

| Longer operation with less maintenance | Less lasting operation with more repairing/maintenance |

| More control on the tuning on the frequnecy and phase, reflection and absorption of microwaves | Control of frequency/power step size is limited |

| More suitable for high power operation | Suitable for low power plasma generation |

| Less affected due to dynamic plasma loading under various plasma applications | More prone to damages and uncontrollable under dynamic plasma loadings. |